Reduce Your Environmental Footprint with the 100% Closed-Loop Recycled Collection

W2W Collection: Recycling Textile Waste into Textile

In its ongoing commitment to reducing its environmental footprint, the Elis Group stands as the sole player to have implemented an ultra-innovative process to recycle textile waste into not just new products, but more importantly, new garments. Partnering with committed actors across the textile value chain, Elis has created the market’s first closed-loop collection featuring fabric made from 100% recycled materials, 60% of which comes from Elis's end-of-life textiles, including flat linen and workwear.

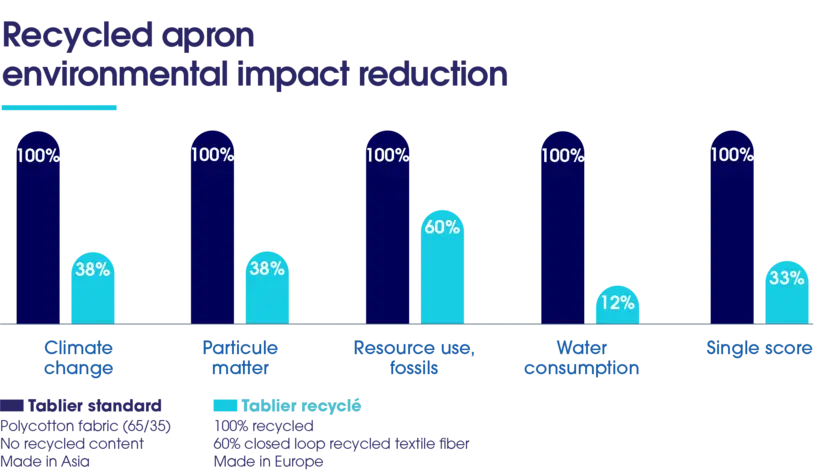

Taking sustainability even further, the apron has also been designed to ensure that all the fabric is used without any lost during manufacturing. To evaluate and compare the environmental impact of this initiative, Elis conducted a life cycle analysis (LCA), contrasting the impact of a standard apron made in Asia with its zero-waste apron.

W2W Zero Waste Apron: The Proof in Numbers

Made from 100% recycled fabric, of which 60% is from Elis end-of-life textiles, this innovative apron generates zero fabric waste during manufacturing, and has a 60% lower carbon impact than a similar standard apron. This unique apron is designed specifically for restaurants, retail and wholesale.

To reach this goal of zero material waste, this apron:

- Uses innovative construction methods.

- Guarantees the use of 100% of the material.

Tablier W2W •

Key figures

-

More than -60% kg CO2eq vs standard apron

Equivalent to 58 km by car avoided.

-

More than -90% L of water vs standard apron

Equivalent to 40 showers avoided.

A rigorous methodology

The LCA was carried out from cradle to gate – in other words, from the raw materials, through production and upstream transportation, up until the dispensers leave the supplier’s logistics site.

The methodology and database used are rigorous and widely recognised: the European Product Environmental Footprint (PEF) methodology on the one hand and the Ecoinvent database, known for its reliability and extensive dataset, on the other.

To model the apron, specific data on the aprons (weight, composition, supply chain) was collected.

A minimal environmental impact

A standard apron is made from 65% polyester and 35% cotton, compared with 100% recycled material, 60% of which comes from Elis end-of-life textiles (closed loop) for the W2W zero waste apron. Some key elements of the study:

- W2W zero waste has a significant lower impact than the standard apron because the different levers are activated:

- Recycled material: 100 %

- Dyeing and weaving with a lower carbon energy mix

- Lower cutting losses

- WtoW apron significantly reduces environmental impact: more than 60% on CO2

- Reduced water consumption: - 90% litres of water

Q&A

-

What is an LCA?

-

What does the scope of the LCA include?

-

Who carried out this LCA?

If you need information or a quote for your project, our teams are here to help. Contact us!

*Required fields

Account details