Clothing dispensers: 100% traceable innovation for hygiene

A Growing need

Across sectors such as healthcare, the food industry, and the service sector, employees may need to change their garments once or even several times a day to remain protected and comfortable while carrying out their work.

Managing the stock of professional garments, knowing who is wearing what, and keeping track of where each item is located can quickly become a true challenge—particularly within large organizations.

More than ever, especially in an exceptional public‑health context, professional garments must be made available to employees in a single dedicated location and distributed in strict compliance with hygiene requirements.

Elis supports you in selecting the most suitable solution for your facility: connected lockers, automatic dispensers for folded garments, or hanger‑based dispensing systems.

Why Install workwear dispensers?

The advantages of automatic distribution are numerous:

-

Hygiene

Every garment, clean or soiled, is always in the right place. Clean garments are stored and distributed individually.

The return hatch for soiled garments enables centralized temporary storage without any risk of airborne contamination. -

Strict traceability and Full visibility over your workwear

The traceability of RFID‑tagged garments enables strict monitoring of compliance with the changing rules established within your facility, as well as full tracking of your stock (which can be adjusted as needed), any damage, and potential losses.

You always know where your workwear is—and you can be certain nothing goes missing.

-

Guaranteed availability

Garments are accessible 24/7, ensuring that users have complete autonomy when retrieving their workwear.

This also gives you the ability to immediately provide clothing allocations for occasional needs, such as temporary staff or new employees. -

Optimized Linen Management

This solution ensures fast distribution, guaranteed hygiene, reduced garment loss, and provides you with a permanent and reliable inventory.

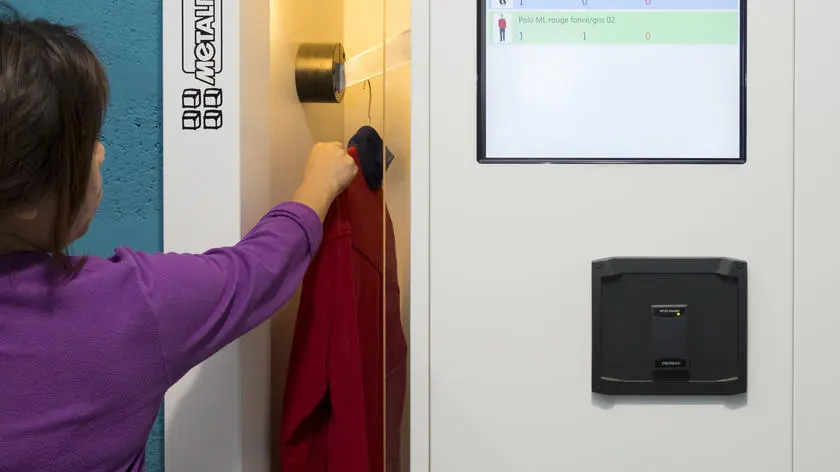

Focus on the connected locker: how does It work?

-

Collecting garments

Users can access the connected locker once they are registered in the dedicated software.

By entering their personal code, the doors corresponding to their access level unlock and are highlighted with green indicator lights. -

Returning soiled garments

Soiled garments are returned through a separate, dedicated unit (with or without a bag) using the simple drop chute—no card or code scanning required.

Each returned item is automatically analyzed and credited back to the user who originally collected it. -

Stock management

The locker can also be used for a wide variety of applications, including controlled distribution of microfiber mop heads and flat linen, as long as items are RFID‑tagged.

The system can be easily expanded by adding slave units next to an existing master unit. -

Additional features of the connected locker

The locker can also be used for a wide variety of applications, including controlled distribution of microfiber mop heads and flat linen, as long as items are RFID‑tagged.

The system can be easily expanded by adding slave units next to an existing master unit.

100% Personalized Support

With more than 20 years of industry expertise, the Elis engineering department is at your service.

Our team supports you from the design of your distribution system through to the implementation of your project: feasibility study, quote, technical installation, staff training, follow‑up, and more.

Elis also advises you on your stock strategy and logistics.

Request an info or a quote

Elis Connect Solution

If you need information or a quote for your project, our teams are here to help. Contact us!

*Required fields

Account details