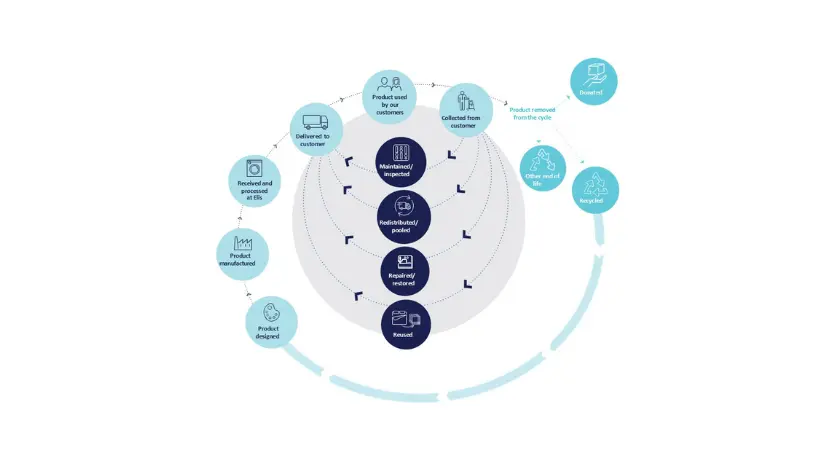

Our circular economy model

Sustainable development is increasingly at the heart of the concerns of our employees, our talent, our customers, our investors and all our stakeholders in general. For Elis, CSR is not a separate programme that runs parallel to the rest of the business; it is inseparable from our daily activities and the Group's development and strategy.

The Group publishes a turnover aligned with the objective of transitioning to a circular economy of 69% according to the European Taxonomy, recognising the virtuous model of the Elis model.

A positive model

At Elis, our business model and our success are based on the circular economy.

At Elis, the circular economy is at the heart of our business model and the foundation of our CSR strategy.

We are convinced that circularity is one of the solutions to today's environmental challenges!

We have been committed to the circular economy for over 75 years, focusing on the use of products rather than their sale. Beyond this model, we rely on sharing, repairing, reusing and recycling to extend the life of materials. Convinced that this model reduces resource consumption and addresses environmental challenges, we work with our partners to continuously improve our practices.

We strongly believe that the circular economy represents a sustainable solution to current environmental challenges and the limitations of our planet.

We regularly conduct Life Cycle Assessments (LCAs) to scientifically demonstrate these benefits:

Eco concevoir nos produits

The products are designed and developed to ensure the highest quality and longevity, taking into account the materials used, their origin, production methods and environmental impact.

Given its business model based on the functional economy (rental and maintenance), the Elis Group has every interest in extending the lifespan of its products by selecting high-quality products that meet expectations in terms of use, comfort and aesthetics, and in working continuously to extend their useful life. The Group aims to reduce the impact of its products and services, in particular by developing products with a lower impact through eco-design (use of alternative or certified materials and products, use of manufacturing processes or designs with a lower impact, design of products with a view to their repair, reconditioning and recycling at the end of their life, reuse and repair, etc.) or conducting life cycle assessments (LCAs) on certain products.

The Elis quality laboratory also tests the resistance of products before they are rolled out, in order to verify that they meet customer needs in terms of performance and durability, in accordance with applicable standards.

Repair, reuse, recycle

We are constantly working to keep our products in use. To do this, we rely on several levers: quality and lifespan, maintenance, reuse, repair, recycling and reconditioning/reassembly. The reuse and recycling of end-of-life products is a priority for the Group. It has therefore set itself the target of recycling or reusing 80% of its end-of-life textiles by 2025. The Group is carrying out numerous actions and initiatives to identify key players in the sector, set up relevant value chains and optimise processes.

Repair

Every day, we repair our customers' clothing in our factories equipped with sewing machines and appropriate accessories. For example, we sew back on loose pockets, replace elastic waistbands and change press studs. Every year in the Netherlands, we carry out nearly 400,000 repairs on more than 2 million items in circulation.

We also repair flat linen.

One of our units in Latvia specialises in repairing and reconditioning carpets. Every year, we repair more than 44,400 carpets from 13 countries: filling holes, replacing edges, adjusting sizes, changing logos, etc. 95% of the carpets we receive are repaired or recut, extending their useful life before disposal.

Repairs are regularly carried out on fountains and sanitary appliances either in the centres or at a workshop in the Paris region, which also reconditions them where necessary.

Finally, our Pest Control business in France encourages the repair of certain traps.

Reuse

Elis mainly offers fungible product rental services. This means that the product is not assigned to or specific to a particular customer. This optimises product use and reduces the risk of obsolescence compared to customer-specific products. The Group has also set up exchanges between laundry plants in three countries, where rotation is limited, via a laundry exchange. As a result, nearly 205,000 items were shared between factories via the linen exchange in 2024 in France, Spain and the United Kingdom, extending the use of this linen and reducing the need for new linen.

Changes in carrier size, the arrival or departure of an employee, and changes in collections are recurring events in a company, which the functional economy can help to resolve.

In France, damaged carrier bags are transformed into new, smaller bags specially designed for delivering small items (e.g. washing gloves). Similarly, in Brazil, hand towels used in the healthcare and hospitality sectors can be dyed black and made available to beauty salons and hairdressers. This means that 1,000 kg of towels are reused every month. Similarly, some cotton towels or sheets are cut up and offered to customers for hire as cleaning cloths. In Estonia, rugs that cannot be repaired are cut up to make samples for customers.

Recycle

The Group develops partnerships and innovates throughout the textile value chain to identify the best ways to recycle its end-of-life products.

We have therefore set ourselves the goal of recycling or reusing 80% of our end-of-life textiles by 2025.

- In France, the first ‘textile to textile’ items (link to our products and services if possible) were designed and woven from recycled yarns using Elis workwear. These products are now marketed in many of the Group's countries.

- In Sweden and Denmark, Elis has been working for several years with a partner whose process is based on chemical recycling technology. Using cotton fibres mixed with wood fibres, it manufactures new synthetic cellulose fabrics.

- In the Netherlands, all end-of-life workwear is mechanically recycled and mainly used to produce insulation materials for the automotive sector. Projects are also underway to test chemical recycling solutions. This means that all clothing managed by the Group is recycled in this market.

To go further, did you know:

- Over 93% of the Group's used flat linen is recycled

- In Europe, barely 1% of textiles are recycled to become clothing again (Environmental impact of the textile and clothing industry, European Parliament, 2019).

- Today, 62% of workwear is recycled within the Group, including 38% for use in new textiles.

If you need information or a quote for your project, our teams are here to help. Contact us!

*Required fields

Account details