Our Cleanroom CSR approach

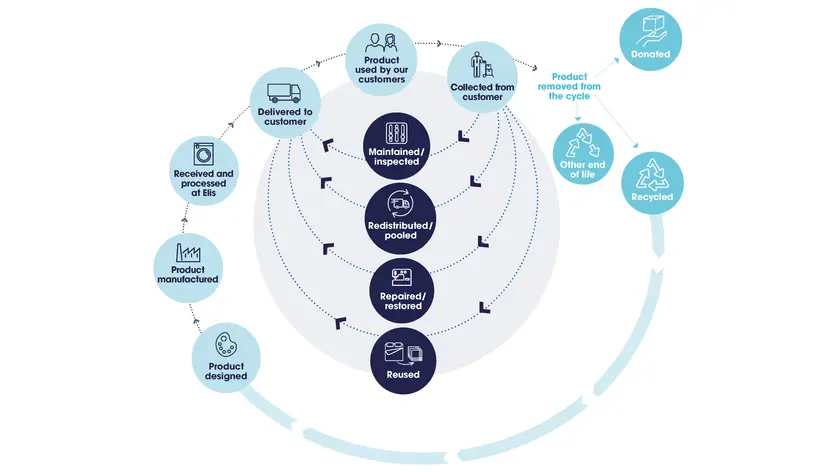

Our business model focuses on services related to products and favors renting over buying. As a result, our CSR approach is at the heart of our daily activities. We strive to reduce our impact on the planet through circularity and exemplary behavior. We empower our employees, support their progress, and seek to have a positive impact on society.

Learn more about the Elis Group's CSR approach

Cleanroom production is subject to very strict regulations in terms of contamination control; our circular service model adapts to each stage of this requirement, such as sterilization, visual inspection, and thorough quality assurance. At the same time, we prioritize the reuse, repair, and sharing of garments in order to optimize their lifespan. Finally, we ensure that our cleanroom textiles at the end of their life cycle are given a new lease on life through reuse, recycling, and energy recovery.

A quest for fairer resource consumption

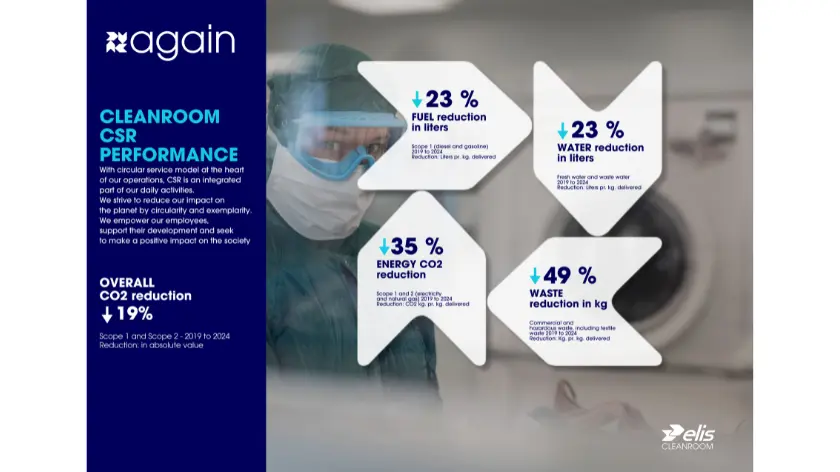

Setting up and maintaining cleanroom production and distribution can be very resource-intensive. Energy, water, and fuel consumption are higher than in a traditional laundry facility. That is why we pay particular attention to reducing our resource use and CO2 emissions.

This quest began a long time ago. Although we have come a long way, there is still much to be done. This is one of the reasons why we have set ourselves science-based targets: to reduce our emissions in line with the Paris Agreement, thereby helping to limit global warming to less than 1.5°C above pre-industrial levels.

-

-19%*

CO₂ emissions for scopes 1 and 2

-

-23%

energy-related CO2 emissions per kg delivered

-

-14%

fuel consumption in liters per kg delivered

-

-15%

water consumption in liters per kg delivered

-

-7%

waste in liters per kg delivered

What environmental initiatives led to these advances?

The answer can be found in the video below.

Sustainable products for cleanrooms

Reducing plastic waste

At Elis Cleanroom, we face a major challenge: a significant proportion of cleanroom manufacturing companies use disposable clothing and accessories, generating large amounts of waste. Furthermore, our certified life cycle analysis of disposable and reusable polyester garments reveals CO2 emissions that are 31% to 62% higher when choosing the disposable option.

That's why we are constantly innovating to find validated alternatives to disposable options. These solutions include visitor clothing kits, consisting of shoe covers, gowns/coveralls, and hairnets, which replace disposable clothing. Reusable sterilization bags help our customers reduce waste when sterilizing their equipment.

Thanks to their large size, reusable cylinder covers contribute significantly to reducing single-use waste. These products complement reusable clothing and circular cleaning solutions used by production employees in clean rooms.

End-of-life textiles

We believe in the circular economy, where waste becomes a resource.

We forge partnerships and innovate throughout the textile value chain to identify the best solutions for recovering value from our end-of-life products, focusing on reuse or recycling. Soon, our recycled products will be made from used products, thus closing the loop of complete circularity. Today, most of our end-of-life products are reused or recycled into insulation and acoustic materials, furniture, and new textile filling materials.

To achieve this, we have launched an ambitious recycling program in collaboration with our partner Alsico Europe:

- All discarded textiles are collected from our sites in a streamlined and sustainable manner.

- They are then sorted and sent for recycling or recovery: textile-to-textile, textile-to-industry, or energy recovery.

We work with the most experienced textile and recycling/recovery partners on the market, researching the latest technologies available and ensuring the most cost-effective and sustainable management of end-of-life textiles.

If you need information or a quote for your project, our teams are here to help. Contact us!

*Required fields

Account details